uPVC Pressure Pipes

About

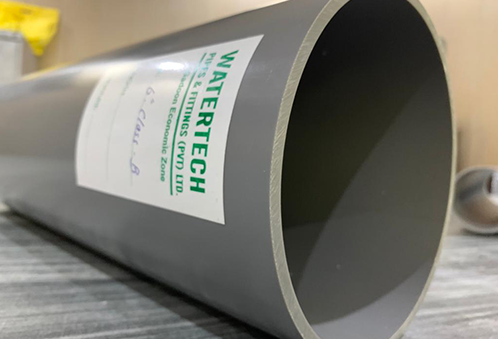

Watertech uPVC Pressure Pipes

Watertech Pipes and Fittings Pvt Limited is on of the key manufactures of uPVC Pressure and Non-Pressure Sewerage/Electrical Conduit Pipes in KPK Province. Watertech U-PVC (Un-Plasticized Polyvinyl Chloride) Pipes with the brand name of Water-Fit and Crystal-Fit are the complete solutions for pressure and non-pressure pipes like boreholes, sewerage, electrical conduits and other water supply applications.

Our Water-Fit brand is made as per BS 3505 Standards and used for bore holes while our Crystal-Fit brand is a suitable solution for soil, waste and vent (SWV), underground drain, electrical conduits and sewerage applications in homes, commercial buildings, community buildings and large scale infrastructure projects.

The Company has state of the art plants and machinery for manufacturing uPVC Pressure pipes according to Pakistan Standard PS 3051-2017 and British Standard BS 3505. Our uPVC Pressure and Non- Pressure sizes range from 2 Inches” up to 10 Inches”.

Usage of Watertech uPVC Pressure and Non-Pressure Pipes

- Boreholes

- Pressure mains and potable water distribution networks

- Drainage installations for sewerage and disposal (both domestic and industrial)

- Industrial effluent disposal –can be used to transport various types of corrosive liquids with aggressive composition

- The casing of commercial cables and wires

- Agriculture, horticulture, and greenhouse irrigation system

- Chilled water line for refrigeration and air –conditioning system

Watertech PIPES RANGE

Nominal Diameter: From 1/4″ to 10″

Sustained working pressure up to 15 bar (150 meter head of water)

WEIGHT OF ASTM D-1785 & 2665

The pipe weights depend on the formulation and density. Approximate weights of WATERTECH PVC Pipes for ASTM D-I 785 for Pressure Pipes & 2665 for Drain, Waste, and Vent are given in the following table.

| Nominal Size | Outer Dia | uPVC Schedule 40 | uPVC Schedule 80 | uPVC Schedule 120 | |

|---|---|---|---|---|---|

| (Inch) | Inches | mm | Nom. Wt kg/mt | Nom. Wt kg/mt | Nom. Wt kg/mt |

| 1/4 | 0.540 | 13.716 | 0.128 | _ | _ |

| 3/8" | 0.675 | 17.145 | 0.167 | 0.211 | - |

| 1/2" | 0.840 | 21.336 | 0.248 | 0.309 | 0.352 |

| 3/4" | 1.050 | 26.670 | 0.329 | 0.419 | 0.464 |

| 1" | 1.315 | 33.401 | 0.483 | 0.615 | 0.692 |

| 1-1/4" | 1.660 | 42.164 | 0.653 | 0.850 | 0.968 |

| 1-1/2" | 1.900 | 48.260 | 0.779 | 1.032 | 1.174 |

| 2" | 2.375 | 60.325 | 1.045 | 1.428 | 1.657 |

| 2-1/2" | 2.875 | 73.025 | 1.650 | 2.177 | 2.409 |

| 3" | 3.500 | 88.900 | 2.160 | 2.916 | 3.439 |

| 4" | 4.500 | 114.300 | 3.074 | 4.264 | 5.537 |

| 5" | 5.563 | 141.300 | 4.169 | 5.915 | ... |

| 6" | 6.625 | 168.275 | 5.414 | 8.139 | 10.636 |

| 8" | 8.625 | 219.075 | 8.154 | 12.364 | 16.818 |

WEIGHT OF BS-3505 & PSI 3051

BSS 3505 does not say any figure for weights. The pipe weights depend on the formulation and density. Approximate weights of WATERTECH UPVC Pipes are given in the

following table.

| Nominal Size | Class-B | Class-C | Class-D | Class-E |

|---|---|---|---|---|

| (Inch) | kg/m | kg/m | kg/m | kg/m |

| 3/8" | - | - | - | 0.11 |

| 1/2" | - | - | - | 0.15 |

| 3/4" | - | - | - | 0.22 |

| 1" | - | - | - | 0.32 |

| 1-1/4" | - | - | 0.41 | 0.50 |

| 1-1/2" | - | - | 0.54 | 0.65 |

| 63mm | - | 0.68 | 0.82 | 0.03 |

| 2" | - | - | - | 0.31 |

| 2-1/2" | - | 1.01 | 1.20 | 1.58 |

| 3" | 3.500 | 1.41 | 1.82 | 2.22 |

| 4" | 4.500 | 2.32 | 3.03 | 3.658 |

| 5" | 5.563 | 3.49 | 4.55 | 5.51 |

| 6" | 6.625 | 5.01 | 6.57 | 7.95 |

| 8" | 8.625 | 7.72 | 10.05 | 12.147 |

PIPE Dimensions for BS-3505 & PSI 3051, Class B,C,D & E

| Wall Thickness | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal size | Outside Diameter | Class B, 6.0 bar | Class C, 9.0 bar | Class D, 12.0 bar | Class E, 15.0 bar | |||||

| Individual Value | Individual Value | Individual Value | Individual Value | |||||||

| (Inch) | min | max | min | max | min | max | min | max | min | max |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| 3/8* | 17.0 | 17.3 | - | - | - | - | - | - | 1.5 | 1.9 |

| 1/2" | 21.2 | 21.5 | - | - | - | - | - | - | 1.7 | 2.1 |

| 3/4" | 26.6 | 26.9 | - | - | - | - | - | - | 1.9 | 2.5 |

| 1" | 33.4 | 33.7 | - | - | - | - | - | - | 2.2 | 2.7 |

| 1-1/4" | 42.1 | 12.4 | - | - | - | - | 2.2 | 2.7 | 2.7 | 3.2 |

| 1-1/2" | 48.1 | 48.4 | - | - | - | - | 2.5 | 3.0 | 3.1 | 3.7 |

| 2" | 60.2 | 60.5 | - | - | 2.5 | 3.0 | 3.1 | 3.7 | 3.9 | 4.5 |

| 2-1/2" | 75.0 | 75.3 | - | - | 3.0 | 3.5 | 3.9 | 4.5 | 4.8 | 5.5 |

| 3" | 88.7 | 89.1 | 2.9 | 3.4 | 3.5 | 4.1 | 4.6 | 5.3 | 5.7 | 6.6 |

| 4" | 114.1 | 114.5 | 3.4 | 4.0 | 4.5 | 5.2 | 6.0 | 6.9 | 7.3 | 8.4 |

| 5" | 140.0 | 140.4 | 3.8 | 4.4 | 5.5 | 6.4 | 7.3 | 8.4 | 9.0 | 10.4 |

| 6" | 168.0 | 168.5 | 4.5 | 5.2 | 6.6 | 7.6 | 8.8 | 10.2 | 10.8 | 12.5 |

| 7" | 193.5 | 194.0 | 5.2 | 6.0 | 7.7 | 8.9 | 10.1 | 11.7 | 12.4 | 14.3 |

| 8" | 218.8 | 219.4 | 5.3 | 6.1 | 7.8 | 9.0 | 10.3 | 11.9 | 12.6 | 14.5 |

| Working Pressure | Field test pressure at 20°C | ||||||

| Class | Bar | kgf/cm² | lbf/in² | Bar | kgf/cm² | lbf/in² | |

| B | 6 | 6.12 | 87 | 9 | 9.18 | 130 | |

| C | 9 | 9.18 | 130 | 14 | 13.77 | 195 | |

| D | 12 | 12.25 | 173 | 18 | 18.38 | 259 | |

| E | 15 | 15.30 | 217 | 23 | 2295 | 325 |

The maximum admissible service pressures are calculated from known data on the basis of a life of atleast 50 years of continuous operation and a safety factor greater than 2.

| Pressure Bar | Class of Pipe |

| 6 Bar | Class - B |

| 9 Bar | Class - C |

| 12 Bar | Class - D |

| 15 Bar | Class - E |

| - | - |