PPrc Pipes & Fittings

About

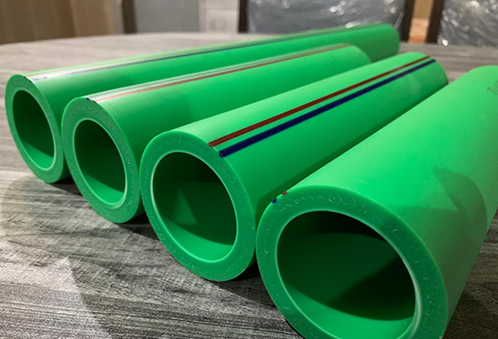

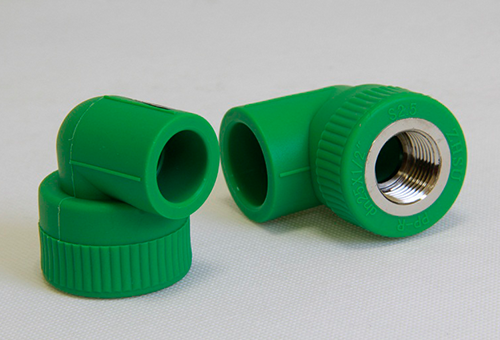

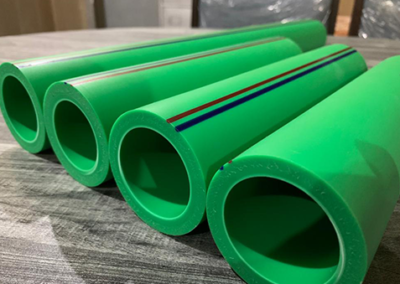

Watertech PPRC Pipes & Fittings

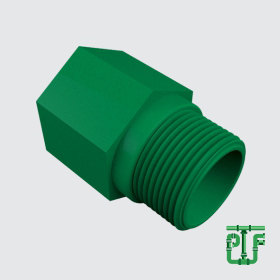

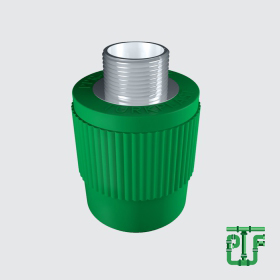

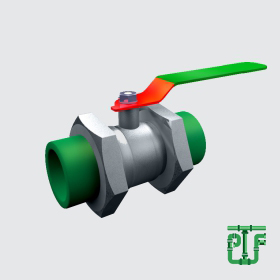

Watertech PPRC Pipes & Fittings are an absolute and perfect solution for supply of hot and cold water and other liquids. PPRC is used in applications of pressured hot and cold water delivery as well as under floor heating in all modern residential apartments, housing & societies, commercial buildings and industries for their high resistance to high temperature and pressure.

Watertech PPRC pipes are made from Polypropylene Random Copolymer which is highly resistant against heat and chemical affects etc and a 100% certified food grade materials. Watertech PPRC pipes are made of 100% pure of imported raw materials while using the latest and advanced high speed PPRC extrusion lines first installed unit in KPK province.

Watertech produces PPRC pipes & fittings up to the following ranges.

Pipes Sizes – 20mm-63mm

Pipes Sizes – 75mm-110mm (Launching Very Soon)

Pressure Rating of PN – PN 12.5, PN 16, PN 20, PN 25

Watertech Produces PPRC Pipes & Fittings as per the following International Standards:

Pipes Standards: DIN 8077/8078

Fittings Standards: DIN 16962

PN-25 as per DIN 8077/78 Standard

| Size (mm) | Minimum Outer Diameter (mm) | Maximum Outer Diameter (mm) | Minimum Wall Thickness (mm) |

|---|---|---|---|

| 20 | 20.0 | 20.3 | 4.1 |

| 25 | 25.0 | 25.3 | 5.1 |

| 32 | 32.0 | 32.3 | 6.5 |

| 40 | 40.0 | 40.4 | 8.1 |

| 50 | 50.0 | 50.5 | 10.1 |

| 63 | 63.0 | 63.6 | 12.7 |

| 75 | 75.0 | 75.7 | 15.1 |

| 90 | 90.0 | 90.9 | 18.1 |

| 110 | 110.0 | 110.9 | 22.1 |

PN-20 as per DIN 8077/78 Standard

| Size (mm) | Minimum Outer Diameter (mm) | Maximum Outer Diameter (mm) | Minimum Wall Thickness (mm) |

|---|---|---|---|

| 20 | 20.0 | 20.3 | 3.4 |

| 25 | 25.0 | 25.3 | 4.2 |

| 32 | 32.0 | 32.3 | 5.4 |

| 40 | 40.0 | 40.4 | 6.7 |

| 50 | 50.0 | 50.5 | 8.3 |

| 63 | 63.0 | 63.6 | 10.5 |

| 75 | 75.0 | 75.7 | 12.5 |

| 90 | 90.0 | 90.9 | 15 |

| 110 | 110.0 | 110.9 | 18.3 |

PN-16 as per DIN 8077/78 Standard

| Size (mm) | Minimum Outer Diameter (mm) | Maximum Outer Diameter (mm) | Minimum Wall Thickness (mm) |

|---|---|---|---|

| 20 | 20.0 | 20.3 | 2.8 |

| 25 | 25.0 | 25.3 | 3.5 |

| 32 | 32.0 | 32.3 | 4.4 |

| 40 | 40.0 | 40.4 | 5.5 |

| 50 | 50.0 | 50.5 | 6.9 |

| 63 | 63.0 | 63.6 | 8.6 |

| 75 | 75.0 | 75.7 | 10.3 |

| 90 | 90.0 | 90.9 | 12.3 |

| 110 | 110.0 | 110.9 | 15.1 |

PN-12.5 as per DIN 8077/78 Standard

| Size (mm) | Minimum Outer Diameter (mm) | Maximum Outer Diameter (mm) | Minimum Wall Thickness (mm) |

|---|---|---|---|

| 20 | 20.0 | 20.3 | 2.3 |

| 25 | 25.0 | 25.3 | 2.8 |

| 32 | 32.0 | 32.3 | 3.6 |

| 40 | 40.0 | 40.4 | 4.5 |

| 50 | 50.0 | 50.5 | 5.6 |

| 63 | 63.0 | 63.6 | 7.1 |

| 75 | 75.0 | 75.7 | 8.4 |

| 90 | 90.0 | 90.9 | 10.1 |

| 110 | 110.0 | 110.9 | 12.1 |

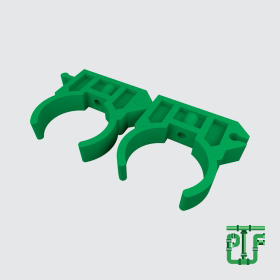

Watertech (PN20) Clamp Space

| Ǿ PIPE | Minimum distance in cm of support of Watertech PPRS 2.5 (PN 20) pipe (horizontal pipeline) at temperature of | |||||

|---|---|---|---|---|---|---|

| mm | 20°C | 30°C | 40°C | 50°C | 60°C | 80°C |

| 20 | 95 | 90 | 85 | 85 | 80 | 70 |

| 25 | 100 | 100 | 100 | 95 | 90 | 85 |

| 32 | 120 | 115 | 115 | 110 | 100 | 90 |

| 40 | 130 | 130 | 125 | 120 | 115 | 100 |

| 50 | 150 | 150 | 140 | 130 | 125 | 110 |

| 63 | 170 | 160 | 155 | 150 | 145 | 125 |

| 75 | 185 | 180 | 175 | 160 | 155 | 140 |

| 90 | 200 | 200 | 185 | 180 | 175 | 150 |

| 110 | 220 | 215 | 210 | 195 | 190 | 165 |

Welding – Getting Started:

01. Cut the pipe at right angle with a cutter.

02. Mark off the welding depth at the pipe end.

03. Simultaneously heat the ends of both pipe and fittings as per recommended heating time.

04. Push the pipe end into the fitting and ensure its alignment of assembly within the specified time period.

Fusion Data For PPRC

| Outer Diameter | Average Heating Time | Average Working Time (Max) | Average Cooling Time (Max) |

|---|---|---|---|

| 20 | 5 | 4 | 2 |

| 25 | 7 | 4 | 2 |

| 32 | 8 | 6 | 4 |

| 40 | 12 | 6 | 4 |

| 50 | 18 | 6 | 4 |

| 63 | 4 | 8 | 6 |

| 75 | 30 | 8 | 6 |

| 90 | 40 | 8 | 6 |

| 110 | 50 | 10 | 8 |

Average Heating Time refers to the start time when the pipe and fitting are inserted up to the marked welding depth in the welding machine.

Advantages of Watertech PPRC Pipes

- Not detrimental to human health

- Rust and erosion free

- Rupture free

- Food grade material

- High resistance to acids and chlorides

- Noise-free at high flow rates

- High-pressure tolerance and rating

- Low weight as compared to GI pipes

- Speed and ease of fusion technology

- Extensive saving in time & labor

- UV resistance

- Low thermal distortion

- Longer life