HDPE/PE Pipes &

Fittings

About

Watertech HDPE/PE Pipes

and Fittings

Watertech Pipes & Fittings Pvt Ltd is one of the leading manufacturers of HDPE/PE Pipes & Fittings including other plastic pipes like uPVC, PVC Garden Hoses, PPRC Pipes & Fittings in KPK, Pakistan. We are acknowledged as a quality producer and a market leader by all our valued customers.

All our production is based on PS and ASTM & DIN Standards. All our products are certified by ISO 9001 2015 both for its quality assurance and management.

Watertech High-Density Polyethylene Pipes and Fittings is an efficient and cost-effective solution for a broad range of water transportation and management in irrigation, municipal, industrial, marine and agricultural it has been tested and proven effective for above ground, surface, floating, and sub-surface marine applications. High-density polyethylene pipe (HDPE) can carry potable water, wastewater, chemicals, hazardous and compressed gases. HDPE has the lowest repair frequency per mile of pipe per year compared with all other pressure pipe materials used for urban water and gas distribution. Polyethylene is a strong, cost-effective, tough, and very durable and reliable solution as compared to GI and other pipes.

Standard Specification

Watertech HDPE/PE pipes are made according to international standards such as ISO-4427 & 4437: 1996, DIN 8074/8075 & PS -3580: 1997 specifications, manufactured in state of the art plant with latest manufacturing technology under strict quality control through state of art lab facilities.

Watertech Pipes & Fittings Pressure Rating

Watertech HDPE pipes operating pressure range between PN-6, PN-8, PN-10, PN-12.5, PN-16 &PN-20.

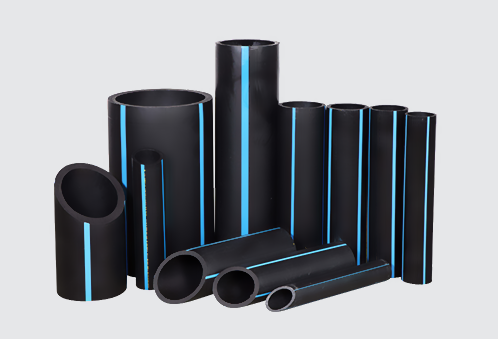

Watertech HDPE / PE PIpe Sizes Range

Diameter Range:

20mm | 25mm | 32mm | 40mm | 50mm | 63mm | 75mm | 90mm | 110mm | 125mm | 140mm | 160mm

Coils Length:

- 20mm to 50mm in 500 feets Coils

- 63mm to 90mm in 100 meters Coils

- 110 mm to 160mm in 4 and 6 meters lengths

Pressure Rating

WATERTECH HDPE/ PE Pipes operating pressure range between PN-6, PN-10, PN-12.5, PN-16

Quality Assurance

WATERTECH HDPE/PE Pipes and Fittings have a State of Art testing laboratory equipped with the latest and modern equipment.

We have the following testing facilities available in the laboratory.

- Melt Flow Rate

- Heat Reversion Test

- Density

- Tensile Strength Checking Test

- Hydrostatic Pressure Test

- Elongation Test

Material

WATERTECH PE Pipes are made from PE 100 black compounds sourced from the finest manufactures.

UV Resistant

WATERTECH HDPE/PE contains carbon black as a UV stabilizer which is one of the most efficient and widely used UV absorbers. Carbon black converts harmful ultraviolet radiation into harmless infrared radiation or thermal energy, which dissipates through the polymer matrix neutralizing the harmful effect of UV. Thus, Watertech HDPE/PE is UV resistant and safe to use in exposed conditions.

Standards

WATERTECH PE pipes for potable water applications are manufactured according to the latest international standard ISO 4427-2(E): 2007 PE pipes for water supply specification DIN 8074/8075 and PS-3580:1997.

Fittings are compatible with ISO (or metric) dimension pipe and conform to the following specifications;

PP Compression fitting: ISO 3458, 34859, 3501, 3503, & B5:5114

PP Butt Fusion fittings: DIN 16963

Technical Specifications

Pressure Rating of Watertech HDPE Pipes:

Max. The working pressure of Watertech HDPE pipes ranges from 6, 8, 12.5, and PN 16 bar. The nominal pressure (PN) corresponded to the maximum allowable working pressure in a bar for the pipe at 20°C, including pressure surge.

Adequate Surge allowance must be taken into account by a pipeline designer.

Max. Working Pressure for Watertech HDPE & PE Fittings

10 bar (Compression Type)

8-16 bars (Butt Fusion Type)

Cold Bending Radii (CBR)

CBR in meters at 20°C = 22 x Outside Diameter of pipe.

Advantages of Watertech HDPE/PE Pipes

-

- Cost-effective and long life

- Leak-Free fully restrained joints

- Easy and quick installation

- Fatigue resistance and flexibility

- Lightweight

- Construction advantages

- Low-pressure loss

- Excellent flow characteristics

- Hydraulically efficient

- Temperature resistance

- High impact resistance

- Don’t alter the odor and taste of water

- Not affected by underground movement.

- The high rapid crack propagation system

- Blacked color pipes are UV resistance

- Ductility

Dimension of Pipe PE 0 100 (Din N – 8074 & 75, ISO – 4427 & 37)

Dimension Tolerance & Pressure Rating Table

| Dimension Ratio | SDR 21 | SDR 17 | SDR 13.6 | SDR 11 | |

|---|---|---|---|---|---|

| PN8 | PN10 | PN12.5 | PN16 | ||

| S.No | Out Side Diameter | Wall Thickness (mm) | Wall Thickness (mm) | Wall Thickness (mm) | Wall Thickness (mm) |

| 1 | 20 | - | - | - | 2.0 |

| 2 | 25 | - | - | 2.0 | 2.3 |

| 3 | 32 | - | 2.0 | 2.4 | 3.0 |

| 4 | 40 | 2.0 | 2.4 | 3.0 | 3.7 |

| 5 | 50 | 2.4 | 3.0 | 3.7 | 4.6 |

| 6 | 63 | 3.0 | 3.8 | 4.7 | 5.8 |

| 7 | 75 | 3.6 | 4.5 | 5.6 | 6.8 |

| 8 | 90 | 4.3 | 5.4 | 6.7 | 8.2 |

| 9 | 110 | 5.3 | 6.6 | 8.1 | 10.0 |

| 10 | 125 | 6.0 | 7.4 | 9.2 | 11.4 |

| 11 | 140 | 6.7 | 8.3 | 10.3 | 12.7 |

| 12 | 160 | 7.7 | 9.5 | 11.8 | 14.6 |

| 13 | 180 | 8.6 | 10.7 | 13.3 | 16.4 |

| 14 | 200 | 9.6 | 11.9 | 14.7 | 18.2 |

Fields of Application

- Fields of Application

- Acid / Caustic Lines

- Chilled Water

- Crude Oil

- Dredging

- Fertilizer

- Hazardous Waste

- Sea Water Effluents

- Slurries

- Utility Piping

- Compressed Air (buried)

- Brine

- Coal Slurry

- De-Watering Pipe

- Drilling Mud

- Fire-Water Mains

- Out Fall Pipelines

- Sewage Treatment

- Storage tank piping

- Cable Conduits

- Cooling Water

- Drain Lines / Industrial Effluents

- Drip Irrigation / Sprinkle irrigation

- Fly ash

- Process Piping

- Sludge Piping

- Underground Services

- Gas (Manufactured as per ISO 4437)

Industrial use of Watertech HDPE

- Agriculture / Drip Irrigation /Sprinklers

- Breweries

- Petroleum and chemicals

- Food processing

- Plastic Resin

- Power generation

- Textile

- Fire mainline

- Fertilizer

- Paper and pulp Glass

- LNG ( liquefied natural gas)

- Mining